What causes the cutting speed of metal laser cutting machine?-Flora

Tiempo de liberación:

2020-08-06

Autor:

Fuente:

The choice of speed of the metal laser cutting machine is very important when cutting materials. If the speed is too slow, no matter how good the effect is, it will affect the production. If the speed

What causes the cutting speed of metal laser cutting machine?

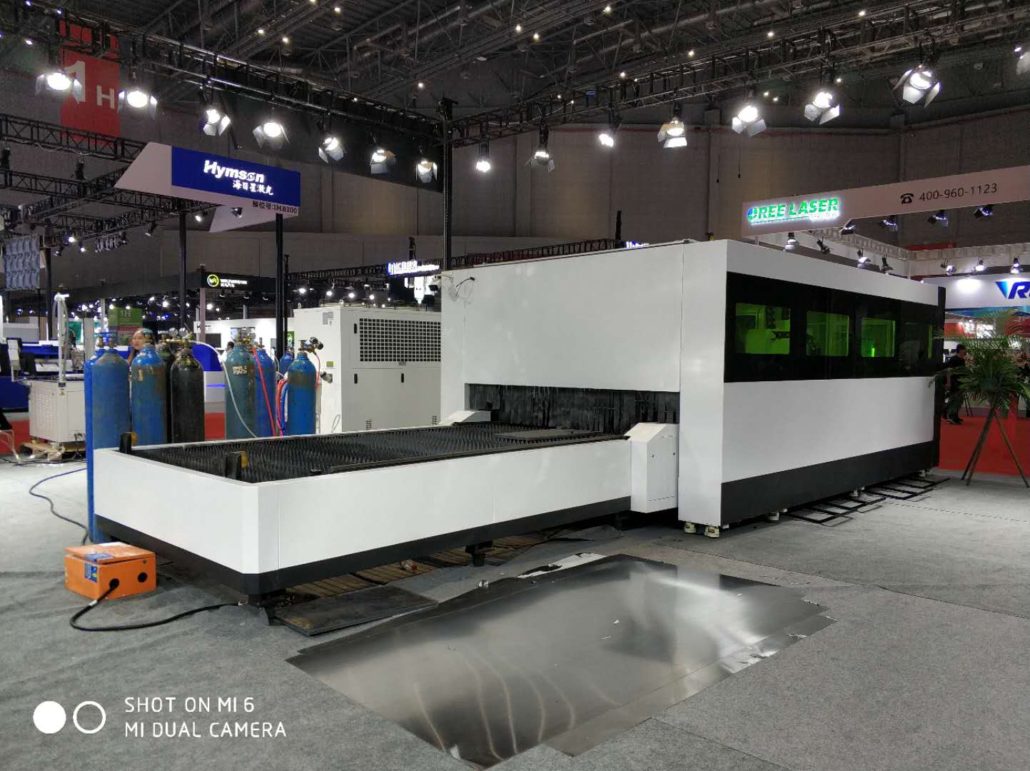

The choice of speed of the metal laser cutting machine is very important when cutting materials. If the speed is too slow, no matter how good the effect is, it will affect the production. If the speed is fast but the quality is sacrificed, it is a bit more than the loss. In fact, the metal laser cutting machine is not so simple in terms of speed control. The cutting speed often needs to be tested according to a range provided by the manufacturer’s technology to find a suitable cutting speed. Because of the difference in the thickness of the cutting material, the composition of the material, ductility, and thermal conductivity, the cutting speed is also different.

General performance:

Firstly, properly increasing the speed of the laser cutting machine can not only improve the quality of the slit, but also the slit is narrow and flat, and can also reduce the deformation of the slit.

Secondly, if the cutting speed is too fast, the line energy of the cutting will be lower than the required amount. During the slitting process, the blowing cannot quickly blow off the molten material, which will cause a large amount of back drag, which will affect the incision. Completeness, and may even need to be processed twice.

Thirdly, if the speed of the laser cutting machine is too low, the cutting part will be exposed to the high temperature of the laser for a long time, which will not only cause the cutting seam to become larger, but also may affect the aesthetics of the cutting seam due to too much heat conduction. The phenomenon of dross forming on the back of the metal.

Fourthly, when the speed is extremely low, the incision will melt too much and the incision will be wider, even causing the arc to go out and the situation that cannot be cut occurs.

Therefore, the cutting speed will affect the cutting quality, not only from the cutting speed, I hope everyone treats it carefully when operating the metal laser cutting machine.

XT laser is manufacturer of laser marking/engraving/cutting/welding/cleaning machines since 2004, any inquiry, feel free to contact us:

Email: xintian131@xtlaser.com

Skype: XTlaser-Flora

Mobile/Whatsapp/Wechat:0086 18354256184

Web: www.xtlaser.com

Palabras clave:

Página anterior

Página siguiente

Página anterior:

Página siguiente:

Dirección: Ningún camino de 866 Chunyuan, distrito del este de Gaoxin, ciudad de Jinan, provincia de Shandong, China