Is Laser Engraving Better for Engraving Mold?-Claudia

Tiempo de liberación:

2020-08-08

Autor:

Fuente:

Many customers asked about how to engraving o Metal mold?The fiber laser marking machine is suitable for mold engraving? Fiber laser engraving are emerging in the mold making. Cause machining small c

Is Laser Engraving Better for Engraving Mold

Many customers asked about how to engraving o Metal mold?The fiber laser marking machine is suitable for mold engraving?

Fiber laser engraving are emerging in the mold making. Cause machining small cavities in molds is difficult, time consuming, and usually need extensive hand polishing.

Deep laser engraving provides an alternative non-contact machining process.It is effective on hardened tool steels and able to access difficult to reach locations.

What Is Deep Laser Engraving?

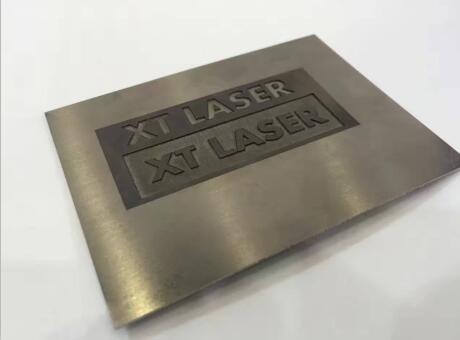

Deep laser engraving is a machining process that removes up to an inch of material. It is frequently to add detail to molds such as patterns and features. It’s different from laser marking,just mark on the surface of the material.

Deep laser engraving is a machining process that removes up to an inch of material. It is frequently to add detail to molds such as patterns and features. It’s different from laser marking,just mark on the surface of the material.

Laser engraving uses higher powered fiber laser systems , typically for laser marking and engraving. The system uses engraving software as well as a range of motion control devices for precise control, and has the ability to engrave flat and contoured surfaces.

Is Laser Engraving Better for Engraving Mold

Deep laser engraving can reduce costs and expand the scope of work performed by tool and die makers. Some of the benefits of laser engraving include:

- Replace milling machines: Laser engraving can replace conventional machining methods for small cavities and reduce overall mold costs.

- Long life: Laser components last longer and require less maintenance than CNC milling machines.

- Surface finish: Laser engraving gives a better surface finish that usually does not require hand polishing.

- Heat-affected zone: Laser engraving has a lower impact on the surface hardness of molds and avoids the risk of micro-fracturing .

- Cost: Running costs are much lower.

A significant benefit of using lasers for engraving molds is that it works equally well on hardened steel surfaces. In this context, it has similar properties , also known as spark eroding. However, it’s generally faster, easier to set up, and requires no expensive consumables such as electrolyte and electrodes.

Email:xintian126@xtlaser.com

Palabras clave:

Página siguiente

Página siguiente:

Dirección: Ningún camino de 866 Chunyuan, distrito del este de Gaoxin, ciudad de Jinan, provincia de Shandong, China